The History – sugar

Sugarcane, the source of sugar, was initially cultivated along the shores of the Bay of Bengal. Its influence gradually expanded to the neighboring regions of Malaysia, Indonesia, Indochina, and southern China. The Arabic peoples played a pivotal role in introducing “sugar” to the Western world during the eighth and ninth centuries. At that time, sugar resembled a sticky, semi-crystallized paste and was thought to possess medicinal properties. The knowledge of cultivating sugarcane and producing this intriguing substance was brought to Sicily and later to Spain.

In the course of the fifteenth century, Venice managed to establish an exclusive hold over this newfound commodity. Initially, Venice relied on importing refined sugar from Alexandria. However, as time progressed, the city-state began acquiring raw sugar and even sugarcane for processing in its own refineries, thus solidifying its monopoly.

This dominance, however, was relatively short-lived. In 1498, the Portuguese explorer Vasco da Gama returned from his voyage to India, bringing the sweet flavoring agent to Portugal. Lisbon quickly embraced the importation and refining of raw sugar. As the sixteenth century unfolded, Lisbon emerged as the European hub for sugar production and refining.

Subsequently, the availability of sugar expanded further. Its presence became notable in France, where it continued to be primarily regarded for its medicinal properties. During the reign of Louis XIV, sugar could even be purchased by the ounce from apothecaries. With the passage of time, particularly in the 1800s, sugar became more widely accessible, although it remained relatively expensive, reaching both upper and middle-class households.

Raw Materials for Manufacturing Sugar.

Sugar is a broad term applied to a large number of carbohydrates present in many plants and characterized by a more or less sweet taste. The primary sugar, glucose, is a product of photosynthesis and occurs in all green plants. In most plants, the sugars occur as a mixture that cannot readily be separated into the components. In the sap of some plants, the sugar mixtures are condensed into syrup. Juices of sugarcane (Saccharum officinarum) and sugar beet (Beta vulgaris) are rich in pure sucrose, although beet sugar is generally much less sweet than cane sugar. These two sugar crops are the main sources of commercial sucrose.

The sugarcane is a thick, tall, perennial grass that flourishes in tropical or subtropical regions. Sugar synthesized in the leaves is used as a source of energy for growth or is sent to the stalks for storage. It is the sweet sap in the stalks that is the source of sugar as we know it. The reed accumulates sugar to about 15 percent of its weight. Sugarcane yields about 2,600,000 tons of sugar per year.

The sugar beet is a beetroot variety with the highest sugar content, for which it is specifically cultivated. While typically white both inside and out, some beet varieties have black or yellow skins. About 3,700,000 tons of sugar are manufactured from sugar beet.

Other sugar crops include sweet sorghum, sugar maple, honey, and corn sugar. The types of sugar used today are white sugar (fully refined sugar), composed of clear, colorless or crystal fragments; or brown sugar, which is less fully refined and contains a greater amount of treacle residue, from which it obtains its color.

The manufacturing process

Planting and Harvesting

Sugarcane really likes warm places with lots of rain, like the tropical and subtropical areas. It needs temperatures around 75 degrees Fahrenheit (23.9 degrees Celsius) and about 80 inches (203 centimeters) of rain every year. How fast sugarcane grows depends on the weather. In warm tropical areas, it becomes fully grown in about seven months, but in slightly cooler subtropical places, it takes longer, about 12 to 22 months.

While sugarcane is growing, people check it from time to time to see how sweet it is. They pay the most attention to the fields where the sugarcane is the sweetest and ready to be harvested. In certain parts of the world, like Florida, Hawaii, and Texas, they use a careful fire to get rid of the dry leaves around the sugarcane. But in Louisiana, they gently cut down the tall sugarcane stalks, which are about six to ten feet (1.8 to 3 meters) tall, and then burn the parts left on the ground.

In the United States, especially places like Florida and other states, machines help with the harvesting. They gather up the sugarcane stalks and put them in trucks or on trains. Then, these trucks and trains take the sugarcane to mills where it gets turned into raw sugar. Sometimes, people still do the harvesting by hand in some states too.

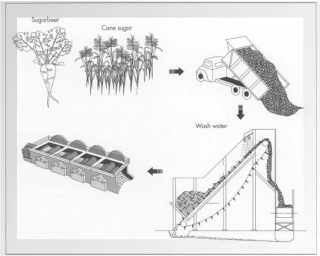

Preparation and processing

Once the sugarcane gets to the mill yards, machines help take it off and get rid of extra dirt and rocks. To make sure it’s really clean, they use warm water to wash it. Sometimes, if there’s just a little dirt and trash, they flood the area with warm water. But if there’s more mess, they put the sugarcane on moving belts that go through strong water sprays and combing drums. This helps get rid of bigger things like rocks, leaves, and trash.

Now, the sugarcane is all nice and clean, and it’s ready for the next step, which is turning it into sugar.

When the sugar beets reach the refinery, they’re given a good wash too. Then, they’re cut into strips. These strips are put into special cells with really hot water, about 175 degrees Fahrenheit (79.4 degrees Celsius). Hot water is sprayed on them from the opposite direction to take out the sugary stuff called sucrose. It’s a bit like a special water dance that helps separate the sugar from the beets.

Juice extraction pressing

Big machines with grooves crush the sugarcane and squeeze out a lot of juice. There are other machines, like fast-spinning shredders, that cut up the sugarcane into small pieces without getting juice out. There are also sharp knives that help cut the sugarcane into small bits. In most places, the shredding happens before the crushing, but sometimes both happen together. They might use one way or even all three ways to get the juice.

After crushing, the sugarcane, they spray it with hot water (or a mix of hot water and juice) to make it less thick. This happens as the crushed sugarcane goes through each machine. The juice that comes out, called vesou, has around 95 percent of the sugary stuff. Then, the sugarcane bits are soaked in water, and the sugar is taken out. They do this by dissolving the sugar in hot water or juice.

Purification of Juice-Clarification and Evaporation

The juice that comes from the machines is a dark green color and is a bit sour and cloudy. To make it clearer and cleaner, they do a process called clarification or defecation. This helps get rid of things that can dissolve in the juice and things that can’t, like sand, soil, and tiny pieces of rock that weren’t removed before. They use a mixture of lime and heat to do this.

Lime is like a magic helper. It’s added to the juice, and it makes the natural sourness go away. Lime also makes tiny particles that aren’t wanted stick together and become bigger. When they heat the juice and lime mix, some things like albumin (a type of protein), fats, waxes, and gums start sticking together too. All these things form a solid part that traps other small stuff in the juice.

Now, for sugar beets, the process is a bit different. The solution from sugar beets gets purified by making some special things called calcium carbonate and calcium sulfite. These things grab onto the dirt and unwanted stuff and become like little bits of solid stuff. These solids grow and trap even more things, and then they’re taken out using a filter that works all the time.

The thick stuff settles down at the bottom, while the clear juice stays on top. They use a special process to get rid of things that aren’t sugar. They use a filter that keeps working to take out all the tiny bits.

The juice that’s now nice and clear still has a lot of water in it, about 85 percent. It’s almost the same as the juice they got from the sugarcane, but now it’s missing the things they didn’t want.

To make the juice even stronger, they take out a lot of the water. This happens by using something called vacuum evaporation. It’s like when water turns into steam, but it happens in a special way. They have four machines in a row, and each one is a bit stronger than the last. Steam from one machine helps the juice in the next one get really hot and turn into steam too. This is called multiple-effect evaporation. The steam from the last machine turns back into liquid, and the thick stuff that’s left behind has about 65 percent good stuff (solids) and only 35 percent water.

The sugary stuff from sugar beets is almost clear now. They also use a special process, like before, where they take out a lot of the water. It’s kind of like when water turns into steam, but it happens in a special way. They do this a few times.

After that, they cool down the thick liquid, put some tiny bits into it, and spin it really fast in a machine. This helps make the sugar crystals. Then, they wash these crystals with water and let them dry.

Crystallization

Making sugar into crystals is the next step. It’s like a sweet science experiment! They use a big pot that works under special conditions, like a vacuum. They fill it with sugary liquid and heat it up. When it gets really thick and full of sugar, they add tiny bits of sugar into it. These tiny bits help other sugar particles stick together and form crystals.

These little bits of sugar are like magic seeds. They’re made by mixing white sugar with a special liquid in a machine for a long time. Then, they add more sugary liquid to the pot and make it thick again. This helps the sugar crystals get bigger.

The crystals keep growing until the pot is almost full. When there’s enough sugar in the mix, they take it out and put it in big containers. It’s like a sugary soup with lots of crystals. These containers are called crystallizers. The crystals keep growing slowly in these containers as they’re gently stirred and cooled down.

Centrifugaling

They use special spinning machines called centrifugals to separate the sugar crystals from the thick syrup, which is called molasses. These machines are like big spinning baskets. Inside the basket, there are metal sheets with tiny holes. The basket spins really fast, around 1,000 to 1,800 times per minute. The sugar crystals stay inside the basket because of the tiny holes, but the molasses goes out through them because of the spinning.

The leftover molasses, called blackstrap molasses, has some sugar, other types of sweet stuff, and some other things like ash and water. It’s stored in big tanks.

After they spin the sugar, they make it into smaller pieces and send it to a machine that dries it. In some places, they make sugar without using these spinning machines. This kind of sugar is darker and made in smaller factories. Most of the world makes sugar using these spinning machines, but some countries make sugar differently

Drying and packaging

Wet sugar crystals are made dry by tumbling them in warm air. Think of it like giving them a warm, gentle hug to take away the wetness. Once they’re dry, they’re separated by size using vibrating screens and put into big storage bins. After that, the sugar is sent to be put into the different packages we find in stores. It can be packed in the bags or boxes we see on grocery shelves, in large containers for businesses, or even as a liquid for big industries to use.

By Produts

The leftover part of sugarcane, called bagasse, is really useful. It’s used to make steam in factories, kind of like how we use wood to make fire. More and more, bagasse is also turned into things like paper, boards, and chemicals.

The parts of sugar beets that are left after taking out the sugary stuff, along with the molasses, are used to feed cows and other animals. It’s been found that sugar beets can make more food for animals per piece of land than other crops in the United States. The leftover beet parts are also treated with chemicals to make something called pectin, which is used in making foods.

After sugar is refined, there’s something left called blackstrap molasses. This is used to feed cows and to make things like alcohol, yeast, and other chemicals. It’s even used to make rum, a kind of drink!